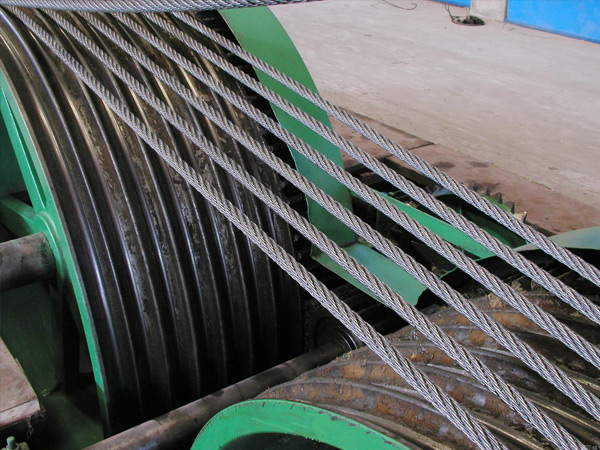

Generally, galvanized steel wire rope will produce some wear, and the wear is also divided into external surface wear and internal surface wear. Then the wear caused by the friction between the surface of the galvanized steel wire rope and the pulley groove is what we call the external surface wear; and the internal surface wear we call is usually the galvanized steel wire rope during use, between the steel wires between the strands Wear due to fretting friction.

If the internal fretting surface wear generated during use of the galvanized steel wire rope has formed extremely severe wear and tear on the surface between the steel wire strands, it will lead to the failure of the galvanized steel wire rope and shorten the life, and will therefore lead to the steel wire Fatigue even breaks, so it also relatively reflects the correlation between wear damage caused by fretting on the inner surface of galvanized steel wire rope and fatigue fracture caused by fretting. The joint action between fretting wear and alternating stress will accelerate the generation and fracture of fatigue cracks of galvanized steel wire rope, because the life of such worn galvanized steel wire rope is greatly shortened, so fretting wear is the failure of galvanized steel wire rope The main reason for the shortened life.

The reasons for the shortened life of galvanized steel wire rope are not only fretting wear, but also other reasons. For example, the external surface wear is because the surface of the material has a certain roughness and ripple, so when the surfaces are in contact with each other and slip, the material shifts and the surface coating peels off due to the deformation, adhesion, and tearing of the adhesion point during relative movement. The resulting loss is the so-called external surface wear. It is precisely because of the sliding phenomenon between the steel wires within the galvanized steel rope that the galvanized steel rope has a problem of wear, because when the galvanized steel rope is put into use, the micro-movement between the steel rope strands is inevitable. Adding pure manganese phosphating film between the galvanized steel rope strands is an effective measure to solve the internal surface wear of the steel rope.